Jet engines are marvels of engineering that have revolutionized aviation, enabling humans to travel faster and farther than ever before. From commercial airliners to military fighters, jet engines provide the thrust needed to propel aircraft through the skies. This article explores the intricate workings of jet engines, delving into their history, fundamental principles, key components, types, and modern advancements. By the end, you’ll have a thorough understanding of how these remarkable machines operate and their critical role in modern aviation.

## A Brief History of Jet Engines

The concept of jet propulsion dates back centuries, with early ideas rooted in rudimentary experiments. In the 1st century AD, Hero of Alexandria demonstrated a simple steam-powered device called the aeolipile, which spun due to steam escaping from nozzles. While not a practical engine, it hinted at the potential of using fluid dynamics for propulsion.

The modern jet engine, however, emerged in the 20th century. In the 1930s, two pioneers—Sir Frank Whittle in the United Kingdom and Hans von Ohain in Germany—independently developed the first practical jet engines. Whittle patented his design for a turbojet engine in 1930, and by 1937, he had a working prototype. Meanwhile, von Ohain’s jet engine powered the Heinkel He 178, the first jet-powered aircraft, in 1939. These early engines were rudimentary but laid the foundation for the rapid advancements that followed during and after World War II.

Post-war, jet engines evolved rapidly, leading to the development of more efficient and powerful designs like the turbofan, which dominates modern aviation. Today, jet engines are highly sophisticated, incorporating advanced materials, computer controls, and aerodynamic optimizations to achieve remarkable performance.

## Fundamental Principles of Jet Engines

At their core, jet engines operate on Newton’s third law of motion: for every action, there is an equal and opposite reaction. A jet engine generates thrust by accelerating a mass of air or exhaust gases backward, propelling the aircraft forward. This process relies on the principles of thermodynamics, fluid dynamics, and combustion.

The basic operation of a jet engine can be summarized as follows:

1. **Intake**: Air is drawn into the engine.

2. **Compression**: The air is compressed to increase its pressure and density.

3. **Combustion**: Fuel is injected and burned with the compressed air, creating high-energy exhaust gases.

4. **Expansion and Exhaust**: The hot gases expand and are expelled at high speed through a nozzle, generating thrust.

This sequence is governed by the Brayton cycle, a thermodynamic cycle that describes the behavior of gas turbine engines. The Brayton cycle involves compressing a gas, adding heat through combustion, and then allowing the gas to expand and perform work (in this case, producing thrust).

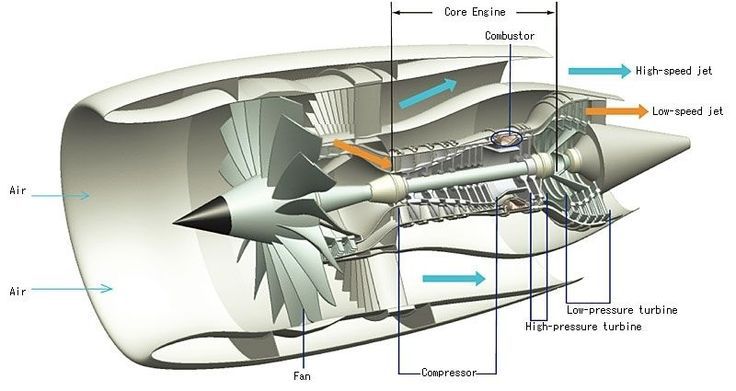

## Key Components of a Jet Engine

To understand how jet engines work, it’s essential to examine their key components. While different types of jet engines have unique configurations, most share the following core elements:

### 1. **Inlet**

The inlet, or intake, is the engine’s entry point for air. Its design is critical for ensuring a smooth and efficient flow of air into the engine, even at high speeds or varying angles of attack. In subsonic aircraft, the inlet is typically a simple duct, while supersonic aircraft use complex inlets with variable geometry to manage shockwaves and maintain optimal airflow.

### 2. **Compressor**

The compressor increases the pressure and density of the incoming air, preparing it for combustion. Modern jet engines use axial compressors, which consist of multiple stages of rotating blades (rotors) and stationary blades (stators). As air passes through each stage, it is compressed further, raising its pressure by a factor of 30 or more in high-performance engines.

### 3. **Combustor**

In the combustor, fuel is injected into the compressed air and ignited, creating a high-temperature, high-pressure gas. The combustor is designed to ensure stable and efficient combustion while minimizing emissions and heat loss. Advanced combustors use techniques like lean-burn combustion to reduce nitrogen oxide (NOx) emissions.

### 4. **Turbine**

The turbine extracts energy from the hot exhaust gases to drive the compressor and other engine accessories. Like the compressor, the turbine consists of rotating and stationary blades. The turbine operates in an extremely harsh environment, with temperatures often exceeding the melting point of the blade materials. Advanced cooling techniques and high-temperature alloys, such as nickel-based superalloys, are used to ensure durability.

### 5. **Nozzle**

The nozzle is the final component, where the high-energy exhaust gases are accelerated and expelled to produce thrust. The design of the nozzle varies depending on the engine type and aircraft mission. For example, supersonic aircraft may use convergent-divergent nozzles to optimize performance at high speeds.

### 6. **Accessory Systems**

Jet engines also include auxiliary systems, such as fuel pumps, control units, and lubrication systems. Modern engines are equipped with Full Authority Digital Engine Control (FADEC) systems, which use computers to optimize performance, fuel efficiency, and safety.

## Types of Jet Engines

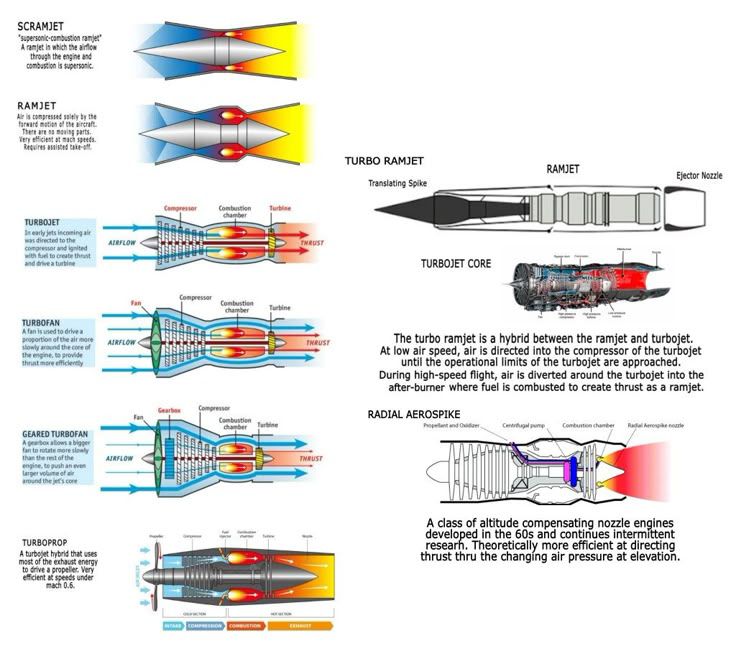

Jet engines come in several types, each tailored to specific applications. The main types are turbojets, turbofans, turboprops, turboshafts, and ramjets/scramjets. Below, we explore each type in detail.

### 1. **Turbojet**

The turbojet is the simplest and earliest form of jet engine. It consists of an inlet, compressor, combustor, turbine, and nozzle, operating as described above. Turbojets are highly efficient at high speeds and were widely used in early jet aircraft, such as the Messerschmitt Me 262 and the Gloster Meteor.

However, turbojets are noisy and fuel-inefficient at subsonic speeds, making them less suitable for modern commercial aviation. They are still used in some military applications, particularly for high-speed interceptors.

### 2. **Turbofan**

The turbofan, or fanjet, is the most common jet engine in modern aviation. It features a large fan at the front of the engine, which accelerates a significant amount of air around the core (bypass air) in addition to the air passing through the combustion process. The bypass ratio, defined as the ratio of bypass air to core air, is a key parameter. Low-bypass turbofans (bypass ratio ~1:1) are used in military fighters, while high-bypass turbofans (bypass ratio ~5:1 to 10:1) power commercial airliners like the Boeing 787 and Airbus A350.

Turbofans are quieter and more fuel-efficient than turbojets, making them ideal for long-range commercial flights. The fan also contributes significantly to thrust, especially at lower speeds, enhancing takeoff performance.

### 3. **Turboprop**

A turboprop engine uses a gas turbine to drive a propeller, which generates most of the thrust. The core engine is similar to a turbojet, but the turbine extracts additional energy to power the propeller via a gearbox. Turboprops are highly efficient at low to medium speeds (below ~400 mph) and are commonly used in regional aircraft, such as the ATR 72 and Bombardier Q400.

While slower than turbofan-powered aircraft, turboprops excel in short-haul operations and can operate from shorter runways, making them ideal for regional routes and remote areas.

### 4. **Turboshaft**

A turboshaft engine is similar to a turboprop but is designed to deliver power to a shaft rather than a propeller. This shaft can drive helicopter rotors, generators, or other machinery. Turboshaft engines are used in helicopters like the Sikorsky UH-60 Black Hawk and in some industrial applications, such as power generation.

### 5. **Ramjet and Scramjet**

Ramjets and scramjets are specialized jet engines designed for high-speed flight. A ramjet has no compressor or turbine; instead, it relies on the aircraft’s forward motion to compress incoming air. Ramjets are efficient at supersonic speeds (Mach 2–5) but cannot operate at low speeds or from a standstill, requiring another propulsion system for takeoff.

Scramjets (supersonic combustion ramjets) are designed for hypersonic speeds (Mach 5 and above). They allow combustion to occur in supersonic airflow, a complex engineering challenge. Scramjets are still in the experimental stage but hold promise for future hypersonic aircraft and spaceplanes.

## The Working Cycle of a Jet Engine

To understand the operation of a jet engine, let’s walk through the working cycle of a high-bypass turbofan, the most common type in commercial aviation.

1. **Air Intake**: As the aircraft moves forward, air enters the engine through the inlet. The fan, located at the front, draws in a large volume of air. A portion of this air (bypass air) is directed around the engine core, while the rest enters the core for compression and combustion.

2. **Compression**: The core air passes through multiple compressor stages, where rotating blades increase its pressure and density. This process raises the air’s temperature and prepares it for efficient combustion. In modern engines, the compression ratio can exceed 40:1, significantly enhancing efficiency.

3. **Combustion**: In the combustor, fuel is injected into the compressed air and ignited. The combustion process occurs at temperatures exceeding 2,000°C, producing a high-pressure, high-velocity gas. The combustor is carefully designed to ensure stable combustion and minimize emissions.

4. **Turbine Operation**: The hot exhaust gases flow through the turbine, causing its blades to spin. The turbine is connected to the compressor and fan via a shaft, so its rotation drives these components. The turbine extracts just enough energy to power the compressor and fan, leaving the remaining energy to produce thrust.

5. **Exhaust and Thrust**: The exhaust gases exit the engine through the nozzle at high speed, generating thrust. In a turbofan, the bypass air also contributes significantly to thrust, especially at lower speeds. The combined thrust from the core exhaust and bypass air propels the aircraft forward.

This cycle repeats continuously during operation, with modern engines achieving remarkable efficiency and reliability through advanced materials, cooling techniques, and control systems.

## Efficiency and Performance Factors

Jet engine performance depends on several factors, including thermodynamic efficiency, propulsive efficiency, and operational conditions.

– **Thermodynamic Efficiency**: This measures how effectively the engine converts fuel energy into useful work. Higher compression ratios and turbine inlet temperatures improve thermodynamic efficiency but require advanced materials to withstand the resulting heat and stress.

– **Propulsive Efficiency**: This measures how effectively the engine converts energy into thrust. Turbofans with high bypass ratios are more propulsively efficient at subsonic speeds because they accelerate a large mass of air at a lower velocity, which is more efficient than accelerating a small mass at high velocity (as in turbojets).

– **Operational Conditions**: Engine performance varies with altitude, temperature, and speed. For example, air density decreases at higher altitudes, reducing the mass of air available for combustion. Engines are optimized for specific operating conditions, such as cruising at 35,000 feet for commercial airliners.

## Advancements in Jet Engine Technology

Jet engine technology has advanced significantly since its inception, driven by the demand for greater efficiency, lower emissions, and enhanced performance. Key advancements include:

### 1. **Materials and Manufacturing**

Modern jet engines use advanced materials like titanium alloys, nickel-based superalloys, and ceramic matrix composites (CMCs). These materials withstand extreme temperatures and stresses while reducing weight. Additive manufacturing (3D printing) has also revolutionized engine production, allowing complex components like fuel nozzles to be made with greater precision and efficiency.

### 2. **High-Bypass Turbofans**

The shift to high-bypass turbofans has dramatically improved fuel efficiency and reduced noise. Engines like the General Electric GE9X and Pratt & Whitney PW1000G feature bypass ratios as high as 10:1, enabling quieter and more economical operation.

### 3. **Digital Control Systems**

FADEC systems optimize engine performance in real time, adjusting fuel flow, compressor blade angles, and other parameters to maximize efficiency and safety. These systems also enable predictive maintenance, reducing downtime and costs.

### 4. **Noise Reduction**

Noise pollution is a major concern in aviation. Modern engines incorporate noise-reducing technologies, such as chevron nozzles (serrated edges on the exhaust nozzle) and acoustic liners, to minimize the impact on communities near airports.

### 5. **Sustainable Aviation Fuels (SAFs)**

To reduce carbon emissions, the aviation industry is exploring sustainable aviation fuels made from renewable sources like biomass or waste. Jet engines can operate with SAFs with minimal modifications, offering a pathway to greener aviation.

### 6. **Hybrid and Electric Propulsion**

While fully electric jet engines are not yet feasible for large aircraft due to battery weight and energy density limitations, hybrid-electric systems are being developed. These systems combine traditional jet engines with electric motors to improve efficiency, particularly during takeoff and landing.

## Conclusion

Jet engines are among the most remarkable achievements of modern engineering, combining principles of physics, advanced materials, and precision manufacturing to achieve extraordinary performance. From the simple turbojets of the 1940s to the high-bypass turbofans of today, jet engines have evolved to meet the demands of efficiency, reliability, and environmental responsibility. As aviation continues to grow and new challenges emerge, jet engine technology will undoubtedly adapt, powering the skies for generations to come.

Write here